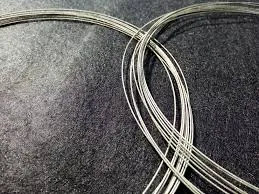

Ceramics are everywhere in modern industry, from automotive exhaust systems and electronic components to filters, insulators, and advanced structural parts. These materials are incredibly hard, heat resistant, and lightweight, but they are also brittle, which makes cutting them a real challenge. That is exactly why diamond wire technology has become the preferred solution. Diamond Wire Loop: Perfect for Ceramics captures the idea behind a cutting method that delivers clean edges, thin kerfs, and reliable precision, even in the most delicate ceramic structures.

Why Ceramics Demand a Specialized Cutting Method

Ceramic materials, especially honeycomb ceramics, are designed with fine internal channels and thin walls. While this structure is ideal for filtration and thermal performance, it makes the material extremely sensitive to vibration and impact. Traditional blades often cause chipping, cracks, or collapse of the internal cells.

This is where Diamond Wire Loop Cutting Honeycomb Ceramic truly shines. The flexible diamond wire applies gentle, evenly distributed cutting force, allowing the ceramic to be sliced smoothly without damaging its structure. For manufacturers focused on quality and yield, this approach is a major step forward.

Understanding the Diamond Wire Loop Advantage

The diamond wire loop is a continuous wire embedded with diamond abrasives that grinds through material rather than forcing a cut. Its flexibility allows it to follow straight lines and curves with equal ease, making it ideal for complex ceramic shapes.

In Diamond Wire Loop Cutting Honeycomb Ceramic, this continuous loop plays a critical role in maintaining stable tension and consistent cutting depth. The result is a smooth surface finish, reduced edge damage, and minimal material loss, which are all essential when working with high-value ceramic components.

The Role of the Ceramic Diamond Wire Saw Cutting Machine

While the wire does the cutting, the Ceramic Diamond Wire Saw Cutting Machine provides the control and power behind the process. Designed specifically for brittle materials, this machine keeps the wire running at precise speed and tension, ensuring steady performance throughout the cut.

A high-quality Ceramic Diamond Wire Saw Cutting Machine allows operators to adjust parameters based on ceramic density, thickness, and structure. Whether slicing solid ceramic blocks or performing Diamond Wire Loop Cutting Honeycomb Ceramic, the machine delivers the accuracy needed to protect delicate internal channels and achieve uniform results.

Ensolltools and Ceramic Cutting Innovation

In the field of precision cutting equipment, Ensolltools has earned a strong reputation for delivering reliable, industry-focused solutions. The company understands the unique challenges of ceramic processing and designs machines that meet those demands head-on.

Ensolltools offers Ceramic Diamond Wire Saw Cutting Machine systems that combine durability with advanced control. These machines are engineered to support demanding tasks like Diamond Wire Loop Cutting Honeycomb Ceramic, helping manufacturers improve consistency, reduce scrap, and maintain high production efficiency. By choosing Ensolltools, businesses invest in technology that is built for long-term performance and real-world reliability.

Comparing Diamond Wire to Traditional Ceramic Cutting Methods

Traditional ceramic cutting methods often rely on rigid saw blades or abrasive discs. While these tools can handle hard materials, they tend to generate vibration and localized stress that brittle ceramics cannot tolerate. This often leads to edge chipping and internal cracks that weaken the final product.

In contrast, a Ceramic Diamond Wire Saw Cutting Machine offers a smoother and more controlled approach. The gradual abrasion of the diamond wire distributes force evenly, making Diamond Wire Loop Cutting Honeycomb Ceramic far safer and more precise. The thin kerf also means less waste and higher yield from each ceramic block.

Applications That Benefit from Diamond Wire Loop Cutting

Honeycomb ceramics used in catalytic converters, diesel particulate filters, and industrial filtration systems are prime examples of where diamond wire excels. These components require exact dimensions and intact internal channels to function properly.

Beyond honeycomb structures, advanced ceramics used in electronics, aerospace, and medical devices also benefit from the clean cuts produced by a Ceramic Diamond Wire Saw Cutting Machine. In all these cases, Diamond Wire Loop Cutting Honeycomb Ceramic represents a level of precision that traditional methods struggle to achieve.

Efficiency, Quality, and Better Yield

One of the biggest advantages of diamond wire cutting is efficiency. Faster cutting speeds, reduced rework, and minimal breakage translate directly into lower production costs. At the same time, the Ceramic Diamond Wire Saw Cutting Machine produces smoother surfaces, reducing the need for additional grinding or polishing.

For manufacturers focused on Diamond Wire Loop Cutting Honeycomb Ceramic, this means better yield from expensive raw materials and more consistent quality across every batch.

Conclusion: Why Diamond Wire Loop Is Perfect for Ceramics

Diamond Wire Loop: Perfect for Ceramics is not just a title, it reflects a proven solution for one of the most challenging materials to cut. By combining the flexibility and precision of diamond wire with the stability of a Ceramic Diamond Wire Saw Cutting Machine, manufacturers can achieve cleaner cuts, thinner kerfs, and higher productivity.

Backed by the engineering expertise of Ensolltools, this technology empowers ceramic producers to meet modern quality standards with confidence. Whether the goal is Diamond Wire Loop Cutting Honeycomb Ceramic or shaping advanced ceramic components, diamond wire cutting offers a smarter, more reliable path forward for precision ceramic processing.